DUOLINE® 10-PE Lining – Extending the life of Tubing in Sucker Rod / PCP wells

DUOLINE 10-PE is a lining system which utilizes a high grade, high density, polyethylene (HDPE) liner for use in rod pump applications for reduction of wear and enhancement of corrosion protection of downhole tubing up to 140° F.

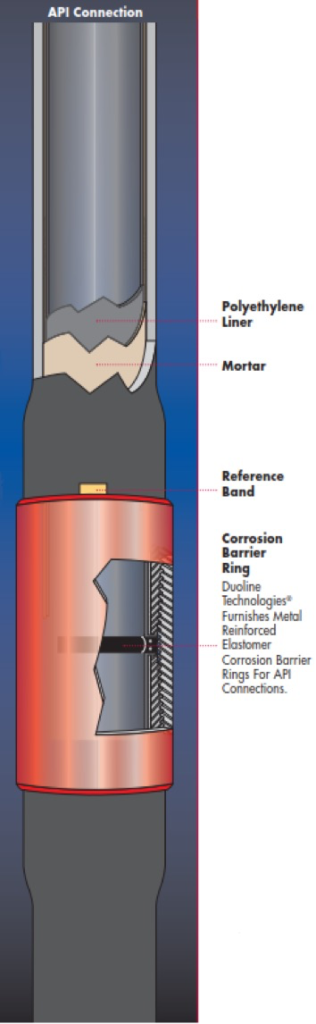

The lining process involves inserting HDPE tubes (liners) into steel pipe and filling the annulus with special cement under pressure. A key design philosophy adopted from Duoline legacy GRE lining system is the Corrosion Barrier Ring (CBR) which protects the J-area in the coupling. Liner ends are flared back against the Pin nose which is compressed against the CBR during connection make up. Liners are manufactured with a knurled pattern on the OD giving it surface roughness which, combined with cement restricts the liner movement.

The benefits of this process include:

- No Voids in the cement filled annulus – permits lining USED tubing

- Grouted annulus provides additional layer of protection

- Improved depressurization collapse resistance with cement backing

- Liner is cemented and not tight fit – ready to use instantly as opposed to 7-10 days setting time.

- No requirement of special / extra-long coupling.

- Apply standard torque make up values.

- CBRs eliminate the need for internally coated couplings.

Benefits of Duoline 10 PE Lining:

- Elastic properties from being a thermoplastic

- Eliminate rod and tubing wear in Rod Pump and PCP wells

- Eliminate rod guides

- Eliminate chemical treatment

- Apply lining on new or USED tubing

- Reduce workover requirements

- Reduce sucker rod load and energy consumption of pumps

- Reduce production costs

Duoline 10-PE Liner Dimensions & Weight

| Pipe Size and Weight | PE Liner Nominal Inside Diameter | PE Liner Recommended Drift Diameter | Added Weight Due to Lining lbs/foot |

|---|---|---|---|

| 2-7/8” # 6.5 ppf | 2.094” | 1.844” | 0.396 |

| 3-1/2” # 9.3 ppf | 2.610” | 2.485” | 0.844 |

| 4-1/2” # 12.6 ppf | 3.520” | 3.270” | 0.811 |